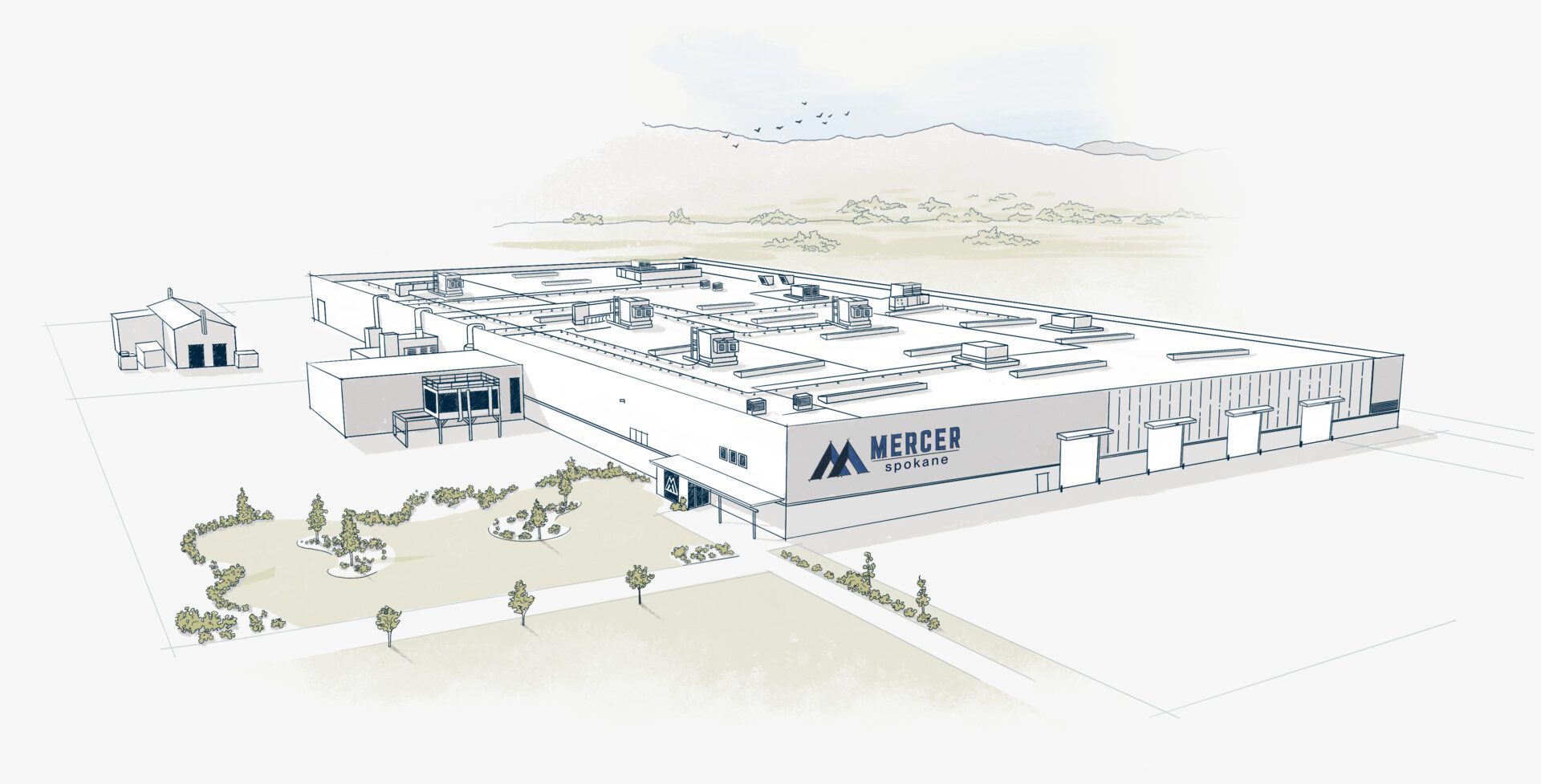

Mercer Spokane mass timber factory

Explore Mercer Mass Timber’s 270,000-square-foot facility in Spokane Valley, Washington.

Climate Sensors Whole-building temperature and humidity control for optimal product quality.

Sorting High-capacity sorting to accelerate raw materials intake and achieve specification.

On-Site Kiln Drying Moisture precision to minimize waste by increasing supply to meet or exceed industry standards.

Horizontal Finger Jointing Connection technique to yield clean, seam-free end product.

Planing Premium 4-sided planer technology to render precise lamstock, enhancing quality.

Pneumatic Press Method used to compress panels during adhesive curing, to create a consistent, quality bond between boards with minimal gaps.

Finishing Three-precision-CNC machines to achieve tight tolerances and pre-manufacture MEPF penetrations for accelerated on-site assembly.

140,000 m3

Annual CLT and GLT production capacity

13,000,000 ft2

Annual 5-ply CLT production capacity

Up to 140

Boards processed per minute

1,400

Number of 12 ft x 60 ft billets produced each month

Factory technologies and capabilities

We have invested in the tools, equipment, and processes needed to consistently deliver best-in-class mass timber products.

Our materials optimization process accounts for lamstock properties, panel shape, and strength and stiffness requirements to maximize performance and minimize waste.

With the largest press in North America, our factory can produce panels up to 12 feet wide by 60 feet long, rivaling the scale of concrete, masonry, and steel.

Our factory can sort and transform more lamstock than any facility in North America, enabling faster assembly.

Access our library of articles, documents, FAQs, and press releases.

Address

Mercer Spokane

19202 Garland Ave.

Spokane Valley, WA

99027

USA

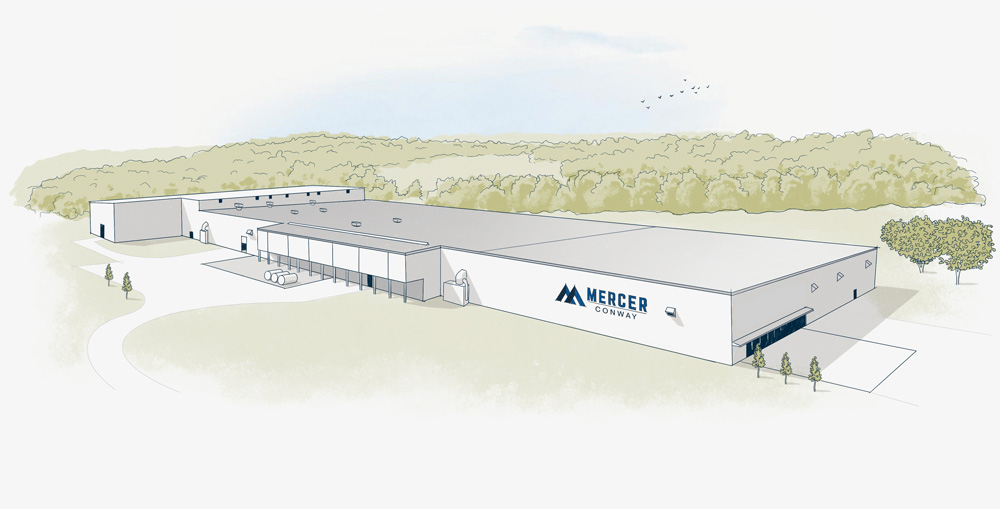

Explore our other factories

Mercer Okanagan

Three facilities strategically located in Okanagan, British Columbia.

Let’s talk

Unlock the potential of sustainable timber construction through innovative, eco-friendly solutions.

Contact our sales team today to learn how.