Home / Resources

Resource

library

Sign up for The Layup

By submitting you agree to our privacy policy and will get commercial communication from Mercer International. We respect your privacy and won’t share your data without consent. Unsubscribe anytime.

Articles

Press releases

Documents

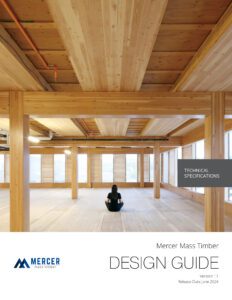

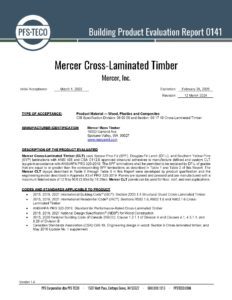

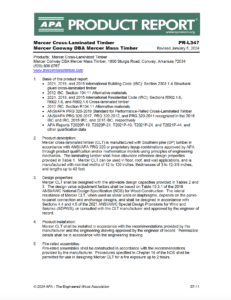

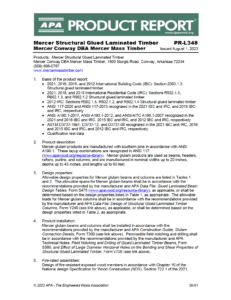

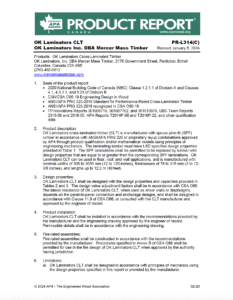

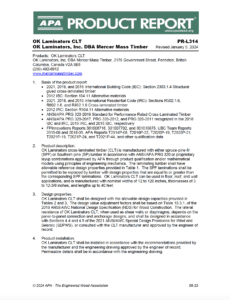

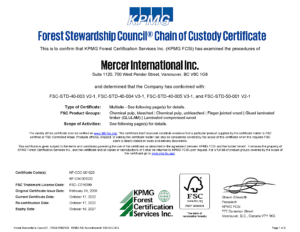

Learn more about the technical specifications of our CLT and GLT, including panel layups, fire and acoustic performance, and environmental certifications.

FAQs

Find contact info as well as answers to frequently asked questions about Mercer Mass Timber below.

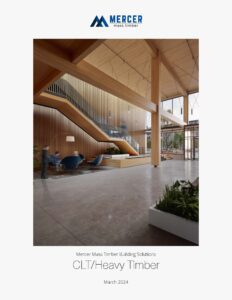

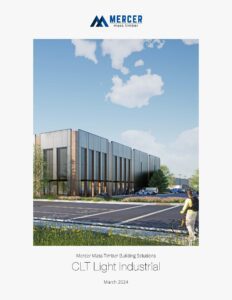

Mercer Mass Timber is an advanced manufacturing company that uses the latest technology to improve how we develop wood engineered products to design and construct buildings. Our factories utilize advanced automation and cross-industry manufacturing innovations to maximize production speed, efficiency, and quality, while maintaining our position as a cost-effective provider of eco-friendly building solutions.

Our facilities in Washington State, Arkansas, and British Columbia are equipped with the world’s largest CLT (cross-laminated timber) presses, enabling us to significantly expand mass timber production in North America and contribute to the industry’s growth. When operating at full capacity, our factories are the top producers of mass timber by volume in the region.

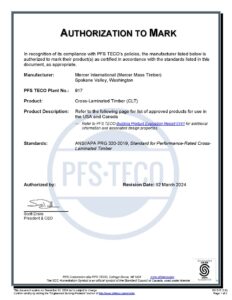

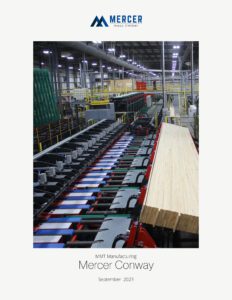

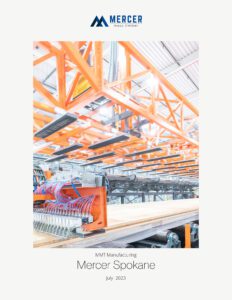

Our state-of-the-art facility, located in Spokane Valley, WA, was constructed in 2019 and acquired by us in August 2021. In 2023, Mercer acquired Structurlam and its subsidiaries, including production facilities in Conway, Arkansas, and Penticton, British Columbia, Canada.

Mercer Mass Timber offers our clients four strategic levers:

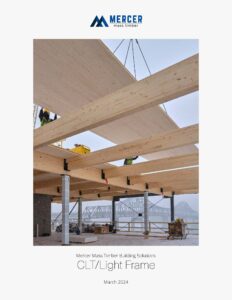

- MMT Project Services: Design-assist solutions for custom projects

- MMT Components & Assemblies: Pre-designed library of high-performance mass timber building components and assemblies

- MMT Manufacturing: Product portfolio of cross-laminated timber floor systems and wall panels, glulam structural beams, and long-length finger joints

- MMT Construction Services: Technology-driven mass timber installation services executed across the U.S., ensuring for timely, budget-compliant, and risk-managed project delivery.

Our production capacity is a significant differentiator. As the largest mass timber manufacturer in North America, MMT represents approximately 37% (2023 Forest Economic Advisors Report) of North American structural CLT capacity. Another differentiator is how we build. We fabricate panels and components inside our factories, decreasing cost and increasing schedule savings for clients. Finally, we optimize the process from end to end, using technology to modernize solutions wherever possible.

Mercer Mass Timber operates from seven locations and maintains offices on two continents. Under the MMT Manufacturing umbrella, we have three factories: two in the United States, located in Conway, Arkansas, and Spokane Valley, Washington, and one in Penticton, British Columbia, Canada. MMT Project Services is based in Vancouver, British Columbia, Canada. In addition, MMT also has access to and support from its large sister company operations located in Germany.

Mercer Mass Timber is wholly owned by Mercer International, a U.S. publically traded company that trades on the NASAQ under the symbol “MERC”.