03/20/2023

Mass Timber Construction: A Comprehensive Guide

Discover the future of construction with our comprehensive guide to mass timber. Learn about the benefits, design and engineering impacts, construction and manufacturing techniques, and sustainable attributes of mass timber. Explore real-world case studies and applications.

Get in touch with Mercer Mass Timber for more information.

What is Mass Timber?

Mass Timber, also known as engineered wood, encompasses an array of structural products that include cross-laminated timber (CLT), glue-laminated timber (GLT), nail-laminated timber (NLT), and laminated veneer lumber (LVL). Mass timber is engineered to be a strong, durable, and sustainable alternative to traditional concrete and steel construction. Because mass timber enables large, open spaces alongside low environmental impact, it is becoming increasingly popular for commercial; residential and multifamily; educational and community; and infrastructure and transportation projects.

Benefits of Mass Timber Construction

Mass timber construction’s benefits include sustainability, strength, faster construction times, cost savings, and a natural wood aesthetic. It has a lower carbon footprint than traditional methods and provides better indoor air quality and acoustics.

- Speed of Assembly

Popular in European markets for over two decades, mass timber construction is shown to accelerate construction by up to 30 percent1. This efficiency is driven by the unique qualities of mass timber and the mass timber planning process.

- Biophilic Properties

- Sustainability Impact

Two of the most ubiquitous conventional building materials, concrete and steel, are among the most carbon-intensive to produce. Switching to lower carbon alternatives can significantly reduce a building’s negative environmental impacts.

- Design Advantage

The design community has enthusiastically embraced mass timber for its ability to create beautiful, functional spaces, and to meet the rising demand for buildings that can be constructed and operated more sustainably.

- Jobsite Efficiency

Greater onsite efficiency is made possible by mass timber. Half the number of workers is typically needed for mass timber installation compared to concrete construction.

- Cost Competitive

Mass timber is cost-competitive. Cost savings are driven by efficiency in materials production, simplified logistics, and reduced labor-hours during installation, making mass timber particularly cost-competitive in markets with high labor rates.

How is Mass Timber Sourced?

Mass timber is sourced primarily from sustainably managed forests in North America, particularly in the Pacific Northwest. These forests are known for high-quality wood, which is used in the manufacturing process of mass timber. The wood is typically harvested from young trees, which have a lower environmental impact. Sawmill residues are also used, minimizing waste.

The most commonly used wood species for mass timber construction in North America is Douglas fir, which is prevalent in the Pacific Northwest. Douglas fir is known for its strength, durability, and versatility, making it an ideal choice for mass timber construction. Other species of wood used in mass timber construction include spruce, pine, and hemlock. These tree species are also sustainably managed and known for their structural and aesthetic properties.

History and Development of Mass Timber

Mass timber construction dates to ancient civilizations. Modern applications, however, were developed in the late 20th century with the invention of cross-laminated timber (CLT) and glue-laminated timber (glulam). Advancements in technology and manufacturing processes have allowed for its versatile and efficient use in projects ranging from residential to commercial, and its popularity continues to grow globally.

Types of Engineered Wood Products

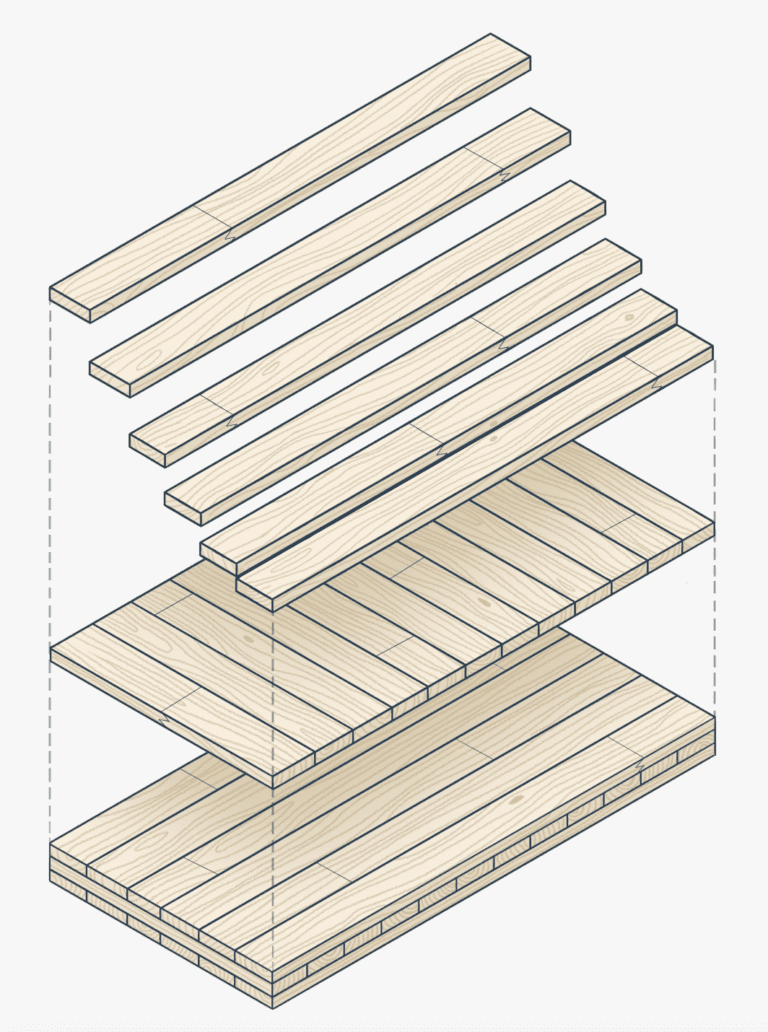

Cross-laminated timber

: A strong, engineered wood product made from layers of lumber glued crosswise at 90-degree angles, bonded them together with structural adhesives. This configuration enhances the material's strength, rigidity, and stability, making CLT suitable for use in large-scale construction projects like walls, floors, and roofs.

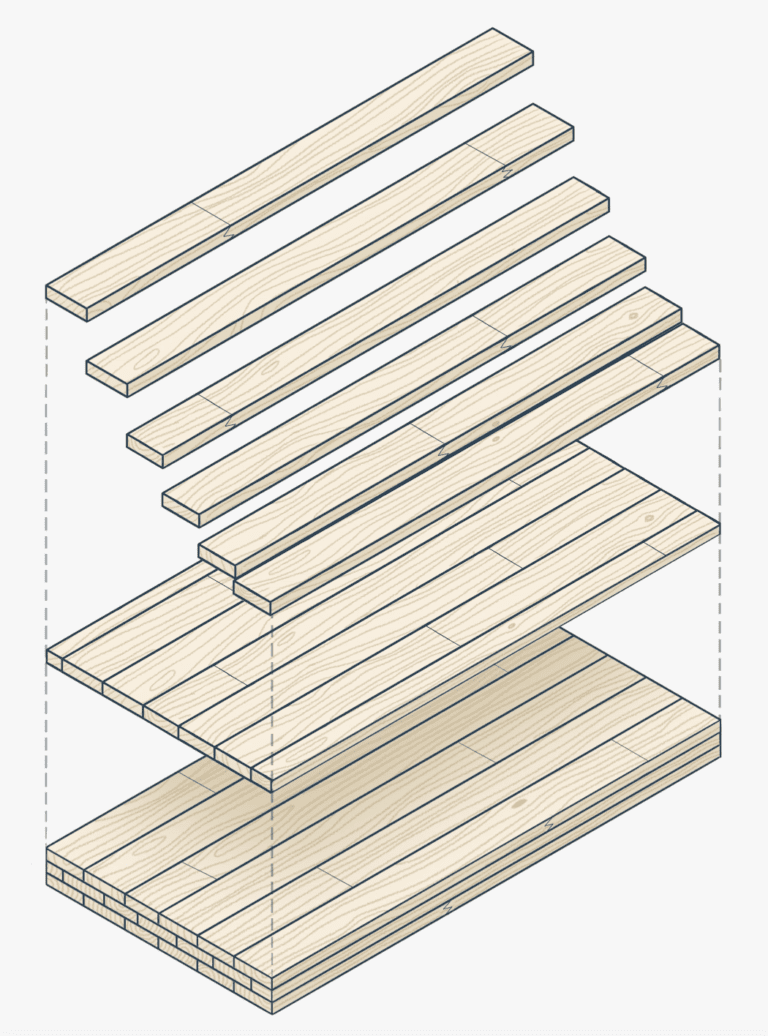

Glue-laminated timber

Manufactured similarly to glulam, GLT panels are typically used in construction for flooring, roofing, or walls, where the weight or load is applied in a single direction. GLT is designed to support loads primarily in one way, making it suitable for applications that require stable horizontal or vertical spans. Unlike CLT, GLT panels do not provide the same level of support in multiple directions.

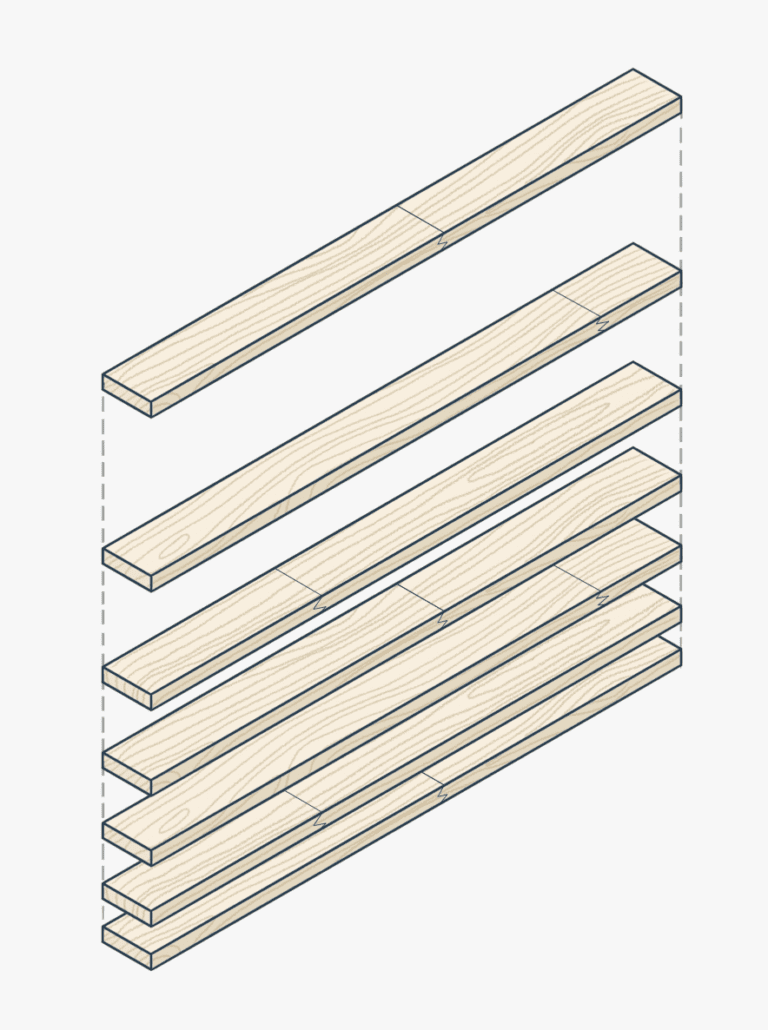

Glulam

Made by bonding together several layers of dimensional lumber with structural adhesives. The layers are aligned in the same direction, allowing the glulam to achieve high strength and load-bearing capacity, making it ideal for beams, columns, and arches in construction. Glulam is prized for its versatility, as it can be manufactured in various shapes and sizes, including curved forms.

Design and Engineering with Mass Timber

Load-bearing Capabilities

Both CLT and glulam have excellent load-bearing capabilities, with strength and stiffness properties comparable to or better than concrete and steel.

Fire Resistance

When exposed to fire, mass timber forms a char layer on the surface that acts as insulation, protecting the uncharred wood underneath.

Seismic Performance

Several studies have been conducted on the seismic performance of mass timber structures, including full-scale shake table tests and computer simulations. These studies have shown that mass timber structures perform well under seismic loading and exhibit less damage and better recovery than traditional building materials such as concrete and steel.

Acoustic Performance

A study conducted by the University of British Columbia in 2016 confirmed that mass timber buildings have excellent sound insulation and absorption properties, providing a quiet and comfortable indoor environment.

Construction and Manufacturing

Factory Production

Factory production ensures that the final product meets the required standards and specifications for building construction. MMT uses computer-controlled machines and specialized equipment to manufacture high-quality mass timber products with consistent dimensions and properties.

Prefabrication and Modular Construction

Prefabrication and modular construction allow components to be produced in a controlled factory setting before they are transported and assembled on site. This approach allows for greater accuracy, faster construction times, and cost savings.

Quality Control and Certifications

Quality control and certifications are crucial for mass timber construction to ensure safety and structural integrity. Organizations such as the American Wood Council and the National Fire Protection Association provide guidelines and codes for design, fabrication, and construction. MMT’s products are also certified by organizations such as the Forest Stewardship Council and the Programme for the Endorsement of Forest Certification to ensure that the wood is sourced from sustainably managed forests.

Sustainability and Environmental Impact

Carbon Sequestration and Footprint

Carbon sequestration refers to the process of capturing and storing carbon dioxide to reduce its concentration in the atmosphere. Trees and forests are natural carbon sinks, and mass timber construction allows for the continued sequestration of carbon throughout the life of the building. The carbon stored in the wood products used in mass timber construction remains stored for as long as the wood is not burned or allowed to decompose. Mass timber buildings not only have a lower carbon footprint than traditional buildings, but continue to actively remove carbon from the atmosphere.

Renewable and Biodegradable

Mass timber is a renewable resource. The wood used for mass timber construction is harvested from sustainably managed forests that are replenished over time. Additionally, mass timber is biodegradable and can be returned to the ecosystem at the end of its useful life, unlike concrete and steel.

Durability and Longevity

Mass timber products are strong, stable, and resistant to decay and insect damage. Properly designed, constructed, and maintained, mass timber buildings have a service life of several decades or even centuries. This makes mass timber construction a cost-effective option, as it reduces the need for frequent repairs and replacements over time.

Case Studies and Applications

The following case studies highlight the natural beauty, efficiency, cost-effectiveness, and sustainable value of mass timber construction.

Conclusion

The Future of Mass Timber

As the demand for sustainable, eco-friendly building solutions continues to grow, we expect mass timber to take center stage. New technologies and manufacturing processes will push the boundaries of what is possible. With the benefits of mass timber becoming clearer, the industry is looking for ways to build ever higher, and imagining solutions for constructing infrastructure and transportation projects out of laminated wood.

How to Get Started with Mass Timber Construction

Learn more about MMT’s extensive mass timber capabilities, and how we can best support your next project as an integrated technical partner or material supplier.